I have a 2002 Jeep Grand Cherokee, with the v8 4.7 motor in it. It is a powerhouse…well, it was a powerhouse. Lately, there have been power issues.

When attempting to accelerate quickly, the Jeep would lose power. It seemed stuck at 3,000 RPMs. The transmission was acting funky and would not shift when it needed to. Going up hills was a real bear.

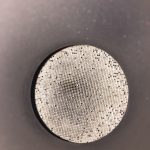

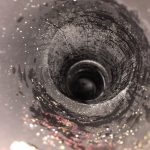

A few weeks ago I noticed the Jeep having issues, and then a check engine light came on. It indicated the upstream O2 sensors needed to be replaced. I drove around like that for a couple of weeks before changing the sensor. I believe that may have, in part, lead to my current predicament. The inside of a catalytic converter looks like a honeycomb, or imagine a bunch of tiny straws taped together. When the upstream sensors failed, the computer did not know what to do to make the motor run properly, so it dumped a bunch of extra fuel into the engine. The catalytic converter’s job is to clean up any junk left in the exhaust, including that extra fuel. It can cause clogs. I am sure this cat was already in poor shape and this was the final nail in it’s coffin.

Now, the 2002 Jeep Grand Cherokee has three catalytic converters on it. Two are directly off the exhaust headers. Those combine in a Y pipe that leads to the third cat. That cat then exits to the muffler and out the rear of the vehicle.

Figuring out which of the three cats went bad can be a pain. With a friend’s ODB tool we made an educated guess that the secondary cat was the problem child and the others were fine (their O2 sensors should have given an indication if not). Catalytic converters are expensive though! So before going and spending a bunch of money on things I wanted to make sure this was the issue. That can be done with a test tube.

Test tubes used to be a thing you could commonly buy, but I think they may have been abused by people not replacing the cats. By the way, your car is required to have a catalytic converter by federal law! Test tubes are simple to build yourself though. To get one into the Jeep, all I did was pull out the trust saws-all, cut the pipe a couple of inches on either side of the cat, and slide new pipe in. The whole operation took less than an hour. Now I can drive around for a couple of days to see if the proper power is back before replacing the cat, or I will know the other two cats also need replacing and have to dig deep into the wallet.

Here are a couple of pictures of the whole operation, and oh boy is the secondary cat clogged! My fingers are crossed the other two are ok.

Video of the difference in sound